Under a non-disclosure agreement

Some of the details in this case study may be vague to protect the client's intellectual property.

Replacement Part Shop

LOVEVERY

Lovevery subscription Play Kits offers curated sets of age-appropriate toys and activities designed to support children's developmental milestones from birth through toddlerhood. After learning that within 2 years, 50% of Lovevery customers will have a second child in the home, we set out to determine the best ways we could support parents making purchases for additional children, while also honoring our promise of sustainability. The result is a self-service shop for replacement parts intended to increase revenue, eliminate friction in our workflow and support families.

My Role

Agile squad design lead

UI design

UX research support

Engineering collaboration

Stakeholder management and presentation

Understanding the Problem

DATA

Our internal research team had recently completed a study which utilized the Kano model, a common methodology for prioritizing product features.

The output indicated that a self-service shop to replace missing or worn-out pieces when a new baby arrives was of highly requested. Parents want to feel like they can offer a new baby the same complete puzzle or unworn rattle their first child enjoyed.

Highlights from the data include:

50% of subscribers on 2yo play Kits have 2+ children

40% of subscribers surveyed indicated they plan to save Play Kit items for future children

45% of respondents with one child would be likely to purchase replacement parts and that increases to 53% for parents of siblings.

Snapshots from the data used to inform the replacement parts shop as a siblings solution.

ALIGNING ON GOALS

Leaning on Internal Partners

After aligning stakeholders on the concept of a self-service shop I conducted interviews with our CX and Ops team members to understand current strategies for addressing replacement part fulfillment and to pinpoint areas of friction in the supply chain. I learned there were several core issues that incurred business costs while also degrade the overall quality of the customer experience:

Time: 67% of customer service communications focused on individual replacement requests

Cost: Variable pricing for replacement parts led to prolonged negotiations, a high revenue/labor cost

Regulatory compliance: We lacked clarity on distinguishing genuine defects from safety concerns

Supply chain: Inefficient systems necessitated labor-intensive handling of one-off replacements

Data management: Inadequate systems hindered tracking and pricing of replacement parts

These challenges collectively contributed to a significant annual loss. Moreover, the absence of consistent internal protocols exacerbated complexities in handling these matters both internally and in customer interactions.

Scenes from stakeholder interviews with CX and Ops stakeholders

Mockups to define search functionality

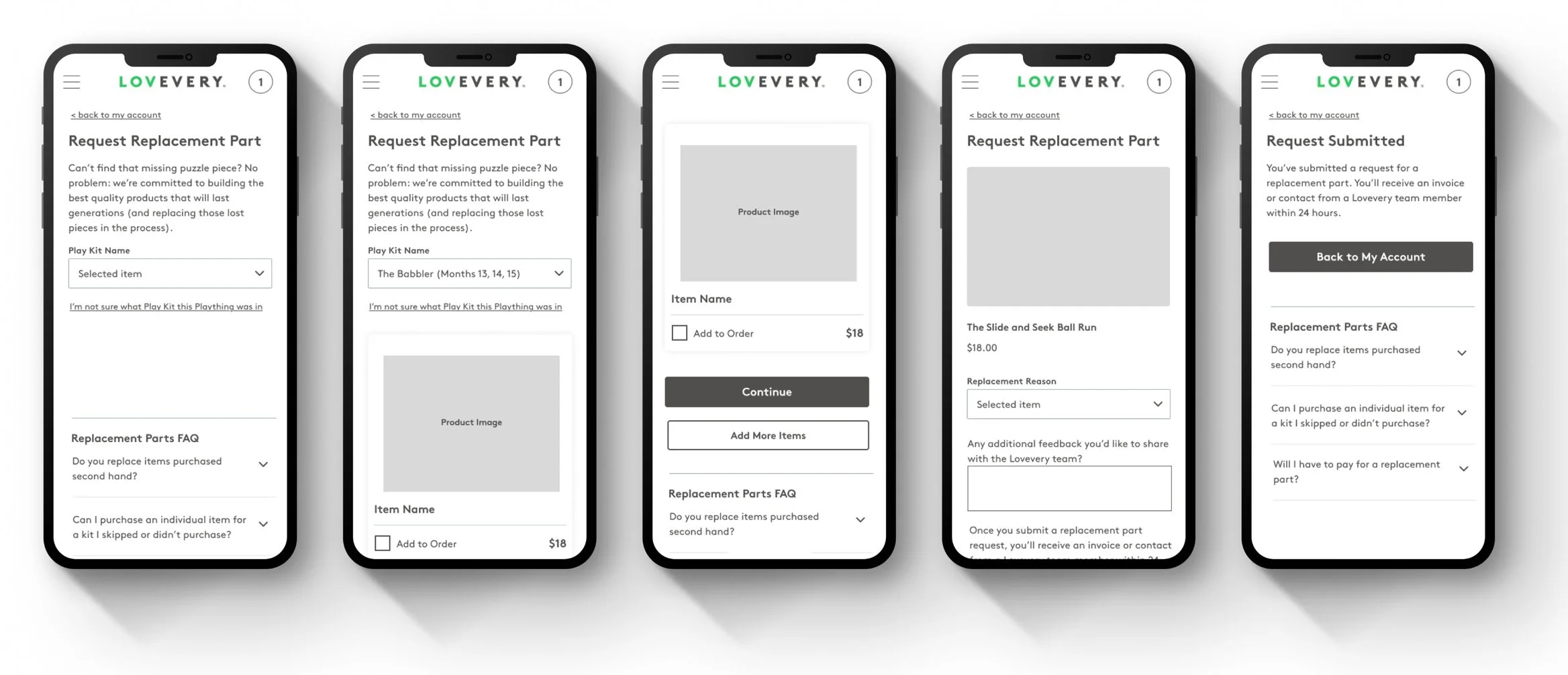

USER TESTING

With our customer and business needs aligned and backed by data, I began crafting mock ups for our self-service replacement parts shop for user testing using our basic product requirements.

Key Features

Gated by login so subscribers can only replace parts they previously purchased

Visual search (due to lack of search functionality on our site)

Clear naming and imagery for each replacement part

Tools for bundling multiple parts from various Play Kits

In partnership with a user researcher, we recruited 5 active subscribers from our testing database who were expecting a second baby soon or have more than one child in the home. We wanted to dig in on how well they could understand the offering, find the product they needed and seamlessly complete a purchase.

Early concept wireframes

Medium fidelity prototype for testing

Photography and Inventory Monitoring

CREATIVE STRATEGY

Our user testing revealed that visual search was a productive way for subscribers to navigate our extensive list of replacement parts. In order for it to work correctly, images had be clearly distinguishable from one another and precisely display the part of the product available for purchase. I provide guidance to our creative team to photograph individual parts to optimize for findability.

The images evolved based on the guidance we provided from user research. The first images were often taken at angles which made it hard to see the product in visible search.

In order for products to be findable, they also had to have descriptive names which wasn’t alwasy the case in our internal inventory lists (ex: FELTBALL_TEAL27). This required pouring through spreadsheets to rename any replacement parts with a vague or redundant name. We also consulted these lists in determining how to group products together to ensure that they were in line with customer need and we were able to fulfill them operationally.

We originally planned to put animal figures in one product grouping and associated card sets in a different one however, CX indicated that often customers request the card/figure set instead.

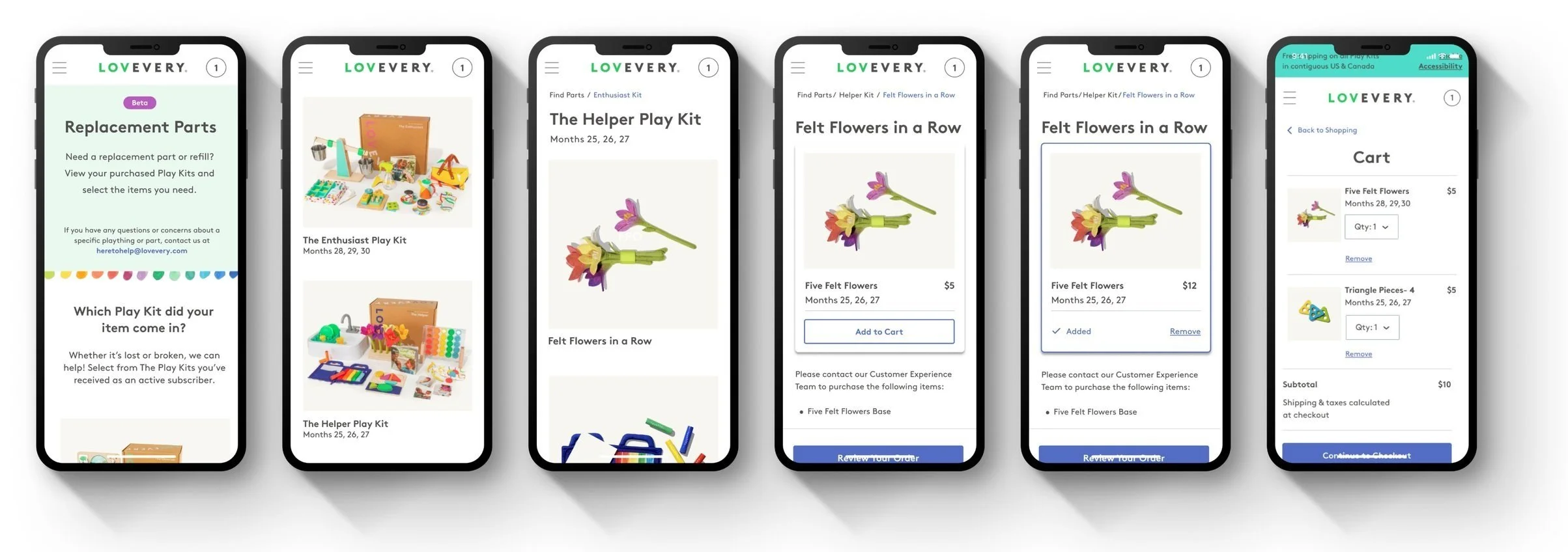

FINAL DESIGN

A high fidelity solution

The final design for our replacement parts shop features a rich visual search with images clearly indicative of your product piece. Products are available to be shipped immediately and at the request of our ops team we added clear markers for backordered/out of stock pieces. After beta testing, CX reported an uptick in inquiries about unlisted items which resulted in us adding messaging in our FAQ about how we make decisions about what to offer in the parts shop.

The Replacement Parts Shop is set to launch in August 2024.